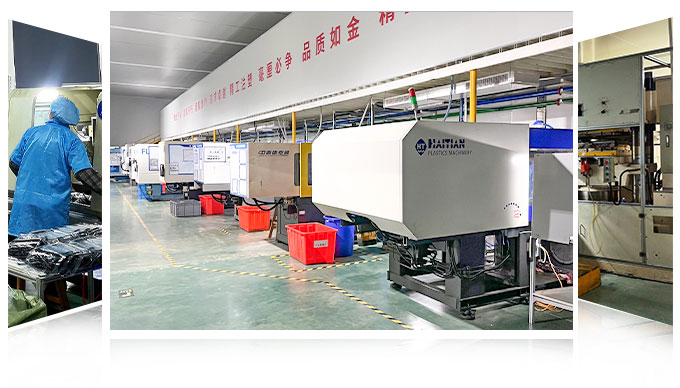

Chengdexing is a professional manufacturer of in mold insert injection molding (IMD, IML, INS) technology products. The company has a superior geographical location and convenient transportation. We are one of the leaders in INS/IMD technology in China, specializing in the design, production, and sales of automotive interior parts, home appliance decorative panels, and medical equipment. The company has advanced equipment such as CNC machining centers, three coordinate machines, electric discharge machines, wire cutting machines, flat screen printing machines, imported high-pressure forming machines, precision punching machines, injection molding machines, vacuum forming machines, etc. The entire manufacturing process from CAD/CAM design and mold opening, printing and molding to injection molding is independently completed by our company. Serve customers with exceptional development progress while ensuring product quality standards. Our company is located in Ninghai, Ningbo, a mold production base in China. The company relies on its unique advantages in advanced mold development, making it the earliest factory in China to develop and produce injection molding technology products for in mold inserts (IMD, IML, INS). Our goal is to provide professional and high-quality in mold insert injection molding (IMD, IML, INS) technology products, and we are dedicated to serving domestic and foreign customers.